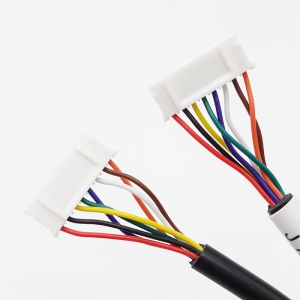

Wire harnesses are the unsung heroes of the modern world, providing structure and connectivity to the electronics that power our daily lives and industries. Their applications are virtually limitless.

Automotive: As previously detailed, this is one of the largest applications. Harnesses are used in every vehicle, from cars and trucks to motorcycles and tractors, managing everything from engine control to infotainment.

Aerospace and Aviation: Aircraft harnesses are subject to the most rigorous standards. They must be extremely lightweight to reduce fuel consumption, yet incredibly reliable to withstand extreme pressure changes, vibration, and temperature fluctuations. They are used in flight controls, navigation systems, and in-flight entertainment.

Medical Equipment: Reliability is paramount in medical devices. Harnesses in MRI machines, patient monitors, surgical robots, and diagnostic equipment must be highly precise, often shielded to prevent electromagnetic interference (EMI), and made from materials that can withstand frequent sterilization.

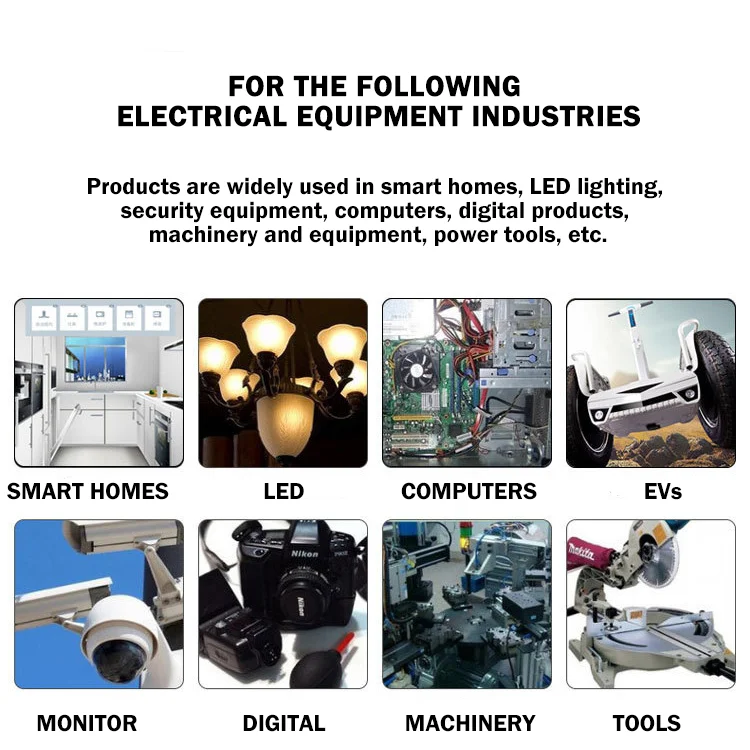

Industrial Machinery and Automation: Factory automation relies on robust harnesses to connect sensors, controllers, motors, and human-machine interfaces (HMIs) on assembly lines, robots, and CNC machines. These harnesses are built to resist oil, chemicals, and constant mechanical wear.

Telecommunications and Data Centers: Massive racks of servers and network equipment require intricate harnesses to manage power distribution and data transmission. High-speed data cables are often bundled together in a harnessed structure for organization, airflow management, and ease of maintenance.

Consumer Appliances: Even simple household appliances like washing machines, refrigerators, and microwaves contain wire harnesses to connect control panels, sensors, and motors neatly and safely.

Military and Defense: Equipment must perform reliably in the harshest environments. Military-grade harnesses are built to exceed standard specifications for durability, temperature tolerance, and resistance to moisture, sand, and shock.

In every case, the harness provides the same core benefits: organization, protection, simplified installation, and enhanced reliability, making it an indispensable component in modern engineering.